Cast-in channels

Cast-in channels

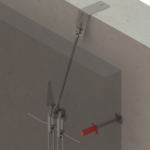

Rebars

Sustainable management of our heritage is an ethical and ecological necessity. It is also an economic imperative, which requires achieving the lowest possible life-cycle cost over the structure’s service life.

In the most exposed parts of the structure, stainless steel reinforcing bars are the most efficient solution to ensure the durability of concrete. Stainless steel rebars are used for repairs and for new works, partially or completely replacing carbon steels, both in precast products and for the execution of cast-in-situ structures.

The FIXGRIP range provides a guarantee of:

In addition to their excellent corrosion resistance which ensures a long service life for structures over several decades, the FIXGRIP range provides a guarantee of:

- Higher mechanical properties than with conventional steel, which allows the use of smaller cross sections or a reduction in reinforcement (meaning weight and labour savings);

- Mechanical properties – yield strength and elongation – meeting the requirements of Eurocode 8, class M for earthquake-resistant construction;

- A selection of non-magnetic stainless steels for buildings where this property is required: hospitals, banks, airports, meteorological stations, etc.

- Mechanical properties at high temperature – tensile and creep – exceeding those of conventional steels, giving improved fire resistance;

- A very low thermal conductivity which gives this product exceptional properties for treating thermal bridges.

FIXGRIP products can be delivered in various forms:

- Welded mesh

- Standardized rebars

- Customized frame shaping

- Wire ties dia. 0.8 mm or 1.2 mm

Advantages

- Propriétés mécaniques élevées

- EUROCODE 8, classe M pour les constructions antisismiques

- tenue au feu améliorée

- faible conductivité thermique

- réductions des ponts thermiques

- Aciers inoxydables amagnétiques

projects

NO RELATED PROJECTS

related products

Cast-in channels

Cast-in channels

Magnetic tools

Magnetic tools

Precast concrete

Precast concrete